HOWDY! I'M THE PROJECT MANAGER OF SKATETRIX SPORT COMPANY!

I'M ERIC MAURER, THE PROJECT MANAGER OF SKATETRIX SPORT COMPANY!

I am a graduate mechanical engineer as well as a graduate mathematician.

I have several years of professional experience in the global industrial business!

Mainly in the Far East: Japan, Korea, China.

But also in Europe, America and beyond in some exotic Asian countries.

Everywhere I have successfully realized many complex and large industrial projects such as:

AMUSEMENT PARKS - LIQUEFIED NATURAL GAS PLANTS - POWER PLANTS - CIVIL ENGINEERING!

SCOPE OF MY COMPETENCIES AS PROJECT MANAGER!

Organization of the cooperation between the companies involved.

Coordination of the system technology.

Procurement and purchasing.

Production and manufacturing worldwide.

Installation and turnkey commissioning.

FINANCIAL SUCCESS at the end of the WARRANTY PERIOD!

REALIZED PROJECT - ROLLER COASTER WHITE CYCLONE

WOODEN ROLLERCOASTER WHITE CYCLONE - JAPAN!

White Cyclone was constructed of enough Alaskan timber to build nearly a thousand homes!

The 1,700 m long track and fast speed will make you scream!

Do not eat before you ride it unless you want trouble with your stomach!

And for those with heart ailments, the ride is not recommended.

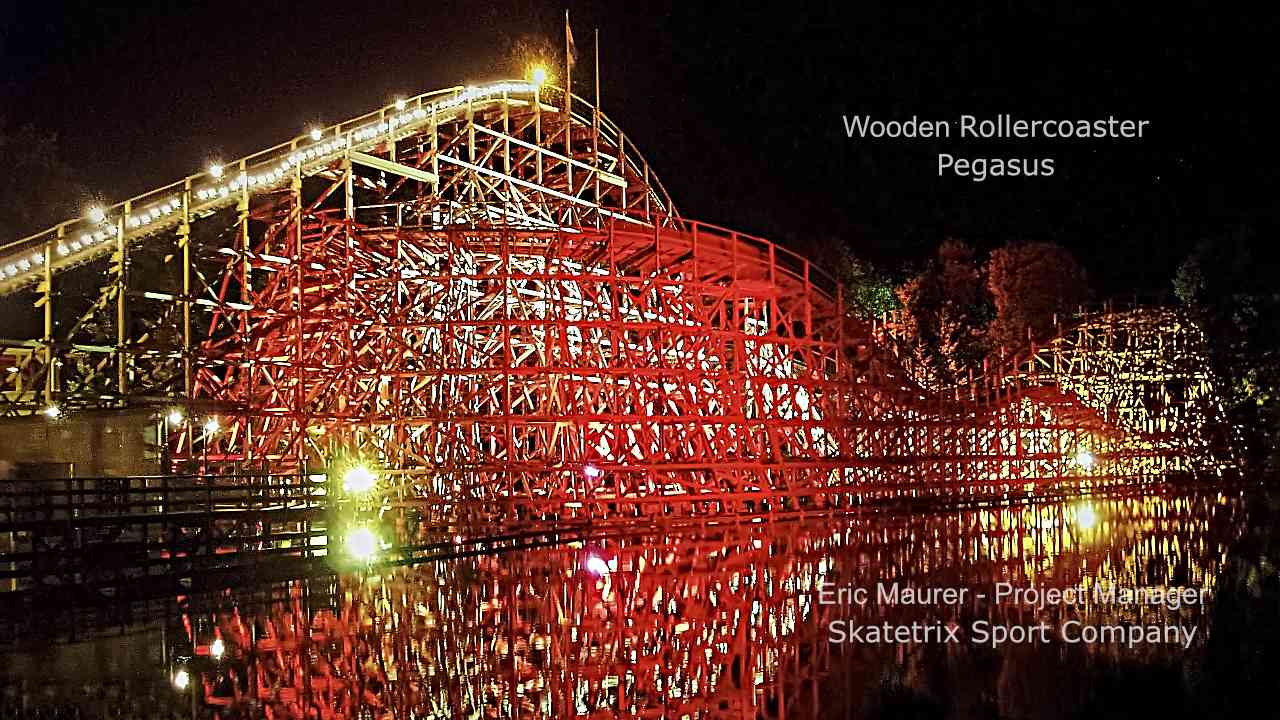

REALIZED PROJECT - ROLLER COASTER PEGASUS

WOODEN ROLLER COASTER PEGASUS - NETHERLANDS!

A smaller roller coaster that was completed within a short time, extensively tested and then approved by the authorities for public operation!

To be exact, within only 6 months! Just in time for the start of the summer vacations!

REALIZED PROJECT - LNG PLANT QATARGAS

LNG PLANT QATARGAS - RAS LAFFAN, QATAR!

Realized in cooperation with Japanese engineering group Chiyoda!

Qatargas 2 and Rasgas 3, both in Qatar, are the largest liquefaction plants worldwide based on capacity.

The liquefaction process consists of cooling down the natural gas to a temperature of about minus 162 degrees Celsius (minus 260 Fahrenheit) thereby turning it into liquid state.

The liquefied natural gas (LNG) is then transported via specifically fitted vessels to consumer markets.